FREE SHIPPING ON

ALL QUALIFYING ORDERS

Enter your email below to join our mailing list:

The modern mortar mixer has its roots in the construction industry of the late 19th century. Prior to this time, mortar was typically mixed by hand using shovels, hoes, or other simple tools. This process was time-consuming and labor-intensive, and the resulting mixture was often uneven in consistency.

In the 1890s, a few inventors began experimenting with motorized mixing machines for mortar. One of the earliest such machines was the “Mortar Mill,” which was patented by J.A. Bement in 1891. This machine consisted of a large drum or trough mounted on a frame, with a motor and gearing system to rotate the drum. The ingredients for the mortar were placed into the drum, which was then rotated to mix the materials.

Over the next few decades, various improvements were made to the design of mortar mixers. In 1905, a patent was granted to F.H. Abbott for a mixer with a paddle-type agitator that rotated inside a stationary drum. In the 1920s, the first portable mortar mixer was developed, which allowed for mixing to take place directly on a construction site.

The post-World War II era saw significant advancements in the design and technology of mortar mixers. In the 1950s, the first hydraulic mortar mixers were introduced, which allowed for more precise control over the mixing process. In the 1960s and 1970s, mixers with multiple drums and other specialized features were developed to meet the growing needs of the construction industry.

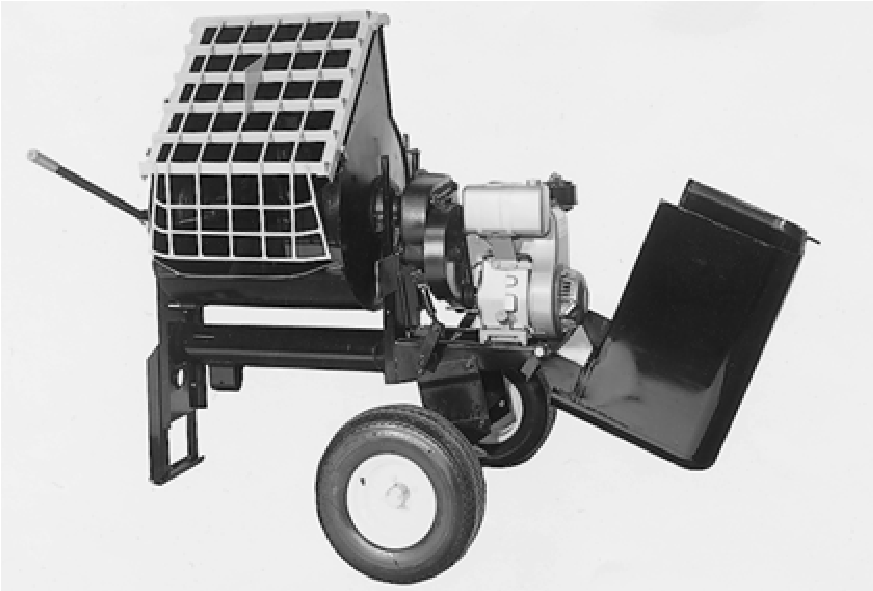

Today, mortar mixers are available in a wide variety of sizes and configurations, ranging from small portable models for DIY projects to large, high-capacity machines for commercial construction projects. They are typically powered by electric or gasoline engines and may use various mixing mechanisms, such as paddles, blades, or spiral agitators, to ensure thorough mixing of the mortar ingredients.

No spam, notifications only about products and updates.

Having dealt with MK Diamond Products and the Delahauts since the mid 1990’s it is sad to hear the news that they have closed their

I’ve told my wife and daughter to never follow a mortar mixer down the interstate. For over 30 years we have sold, rented, and repaired

This question is one of the most frequent mixer related questions our rental staff are asked. Our contractor customers know the importance of using the right tools for the job.

Trowel Trades, a company that specializes in equipment rental, tool retail, repair services, scaffolding and mast climber access solutions, enters the Silver Tier of the Masonry Alliance Program.

Your email was submitted successfully.

YOUR 10% OFF COUPON CODE IS WELCOME10.

See category exclusions below.

Category Exclusions:

Arbortech Brick and Mortar Saw, Compaction, Concrete Mixers, Concrete Walk Behind Saws, Drop Hammers, Grout Hogs, iQ Power Tools, Masonry Block Saws, Masonry Brick Saws, Mast Climbers, Mortar Mixers, Mud Buggy, Saws, Scaffold, Self Dumping Hoppers, Shoring, and Stihl