FREE SHIPPING ON

ALL QUALIFYING ORDERS

Enter your email below to join our mailing list:

The following article is of unknown origin from 1997. I happened upon it in our data archives (which date back to about 1992) while I was searching for parts to a Muller mixer that a customer is trying to repair. I felt it was a fitting start to the series we have been working on here at Trowel Trades inc dealing with the history of the modern mortar mixer. This article will serve as part one of the series. If you sold, shopped, purchased or used mixers in the 1990’s this should take you back.

So without further ado, we present……………

What’s NEW in Mortar Mixers (1997 Edition)

Manufacturers this year are touting hydraulic drive systems, safety features, longer drum life, and a bigger selection of sizes

They’re bigger. They’re smaller. They’re reportedly easier to operate and maintain. The 1997 lineup of “conventional” mortar mixers focuses on flexibility—meeting the needs of both

contractors that do large-volume jobs and those that primarily do repair work.

Manufacturers emphasize operator safety and convenience in their literature. One company promotes its ability to customize a mixer to accommodate space constraints: Components can be configured in a mirror image of what is typical and paddle movement reversed, to allow the operator to stand in a specific location.

Hydraulic-drive systems are becoming more popular. Hydraulic mixers permit the operator to reverse the paddle shaft to back out of a jam. Without belts or gears, these machines are said to simplify maintenance, and they run more quietly.

Contractors in the market for a mortar mixer should compare the seal systems and paddle configurations of various models, because these differ among manufacturers. Also consider the quality of the steel used in the drum and other components. Since a mortar mixer is probably the most used and abused piece of equipment on-site, look for features that indicate durability (see How to Select a Conventional Mortar Mixer, March 1993, pages 119-121.) And always ask about the manufacturer’s warranty. The following review highlights some of the newest mortar mixer models. All the information was provided by the manufacturers.

Stow hydraulic mixer allows paddle reversal Powered by a 13-hp engine, this mixer from Stow comes standard with a hydraulic dump that allows the operator to dump a full drum by pushing one lever. The paddle shaft can be reversed, making it safer and easier to clear obstructions. The mixer has a total capacity of 13.8 cubic feet and a batch capacity of 12.5 cubic feet and carries a five year warranty. Paddle speed is adjustable—up to a maximum of 40 rpm. The machine also has an easy-to-access filter.

Muller stresses durability of Model 306 Available with a variety of power options, Muller Machinery’s Model 306 mortar mixer has a batch capacity of 6 cubic feet (1 1 ⁄2 to 2 bags). For strength and durability, the unit features 7-gauge drum shells with 3 ⁄16-inch flanged drum heads and 11⁄2 -inch solid-steel square paddle shafts. Double paddle-shaft seals and heavy-duty paddle-shaft bearings also are said to provide long life. A T-shaped tubular-steel frame allows better wheelbarrow access.

Spray Force mixer has helical paddles Powered by a 12-hp gas engine, Powermix 921 by Spray Force has a 13-cubic-foot drum built with 31 6⁄ – i n c h steel plate. Double bearings at each end of the drum are designed to provide greater shaft support and smoother drum rotation. Helical-designed cast-steel paddles mix mortar quickly and evenly with little splashing, according to the manufacture r. The heavy duty gear drive has no belts, pulleys, or chains; the clutch and gears are sealed in an oil bath for continuous lubrication.

Whiteman mixer has 3⁄16-inch steel drum. This 7- cubic-foot mixer features cast steel paddle arms with rubber blades for a clean and uniform mix, according to Whiteman Industries Inc., the manufacturer. The paddle shaft consists of 1 3⁄4-inch square hardened steel, and the drum, 3 ⁄16-inch steel. The engine’s steel cover has punched ventilation openings for increased cooling and added strength.

Mighty’s Mortar Hog has a 15-cubic-foot capacity Called the Mortar Hog, Model 150 by Mighty Equipment Inc. is a hydraulically driven mixer with a maximum capacity of 15 cubic feet. The large size makes it especially suitable for use with a silo-dispensing system. The operator can reverse the paddle direction to unclog the machine easily. This high torque mixer requires little maintenance, according to the manufacturer, which offers a 30-day money back guarantee.

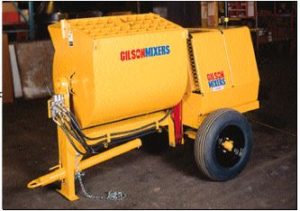

Gilson mixer has hydraulic drive This model, by Gilson Mixers, has a capacity of 12 cubic feet or four bags. The machine’s hydraulic drive has an overload bypass to help contractors avoid costly repairs to the paddles and shaft system in the event of a jam. Hydraulic controls are located at the tow end of the mixer for efficient operator control. Four mixing paddles and two end scrapers, all with adjustable rubber wipers, are mounted on a square paddle shaft for extra strength. The square shaft configuration is designed to eliminate problems with paddles twisting on the shaft. The manufacturer can customize mixers to meet the needs of individual contractors.

Anchor All power options available for Anchor mixer Mixers by Anchor are designed and built to contractor specifications. All power options are available. This 6-cubic-foot model has spiral elliptical blades for fast and thorough mixing, a high-speed 48 inch trailing axle, and 20-inch pneumatic tires. The machine has a completely sealed gear reduction unit, with all gears and bearings running in a bath of clean oil. Equipment options include refractory blades, rubber blades, a drum liner, and a water meter.

Hydraulic Mudpumps Reverse button on Hydraulic Mudpumps mixer permits instant paddle reversal This 8-cubic-foot mixer from Hydraulic Mudpumps Inc. features a direct-drive hydraulic motor, which eliminates belts, clutches, and gears that can wear out or break. The operator can start or stop the mixing paddles by pulling or pushing a hydraulic-valve button. In addition, the paddle direction can be changed by pulling up on another button. This makes it easier to remove objects that become caught between the paddles and the drum. A pressure relief valve protects the hydraulic power system and paddles.

Imer’s Mix 60 blends 60 to 80 pounds of mortar Weighing 64 pounds, Mix 60 is a portable vertical shaft mortar mixer by Imer U.S.A. Inc., which blends 60 to 80 pounds of mortar, stucco, or grout per batch. To transport the mixer, just pull it along like a piece of luggage, states the manufacturer. Powered by a direct-drive motor/gearbox combination, the machine is designed for restoration work or jobs in confined spaces. The mixer has a 55-rpm paddle speed.

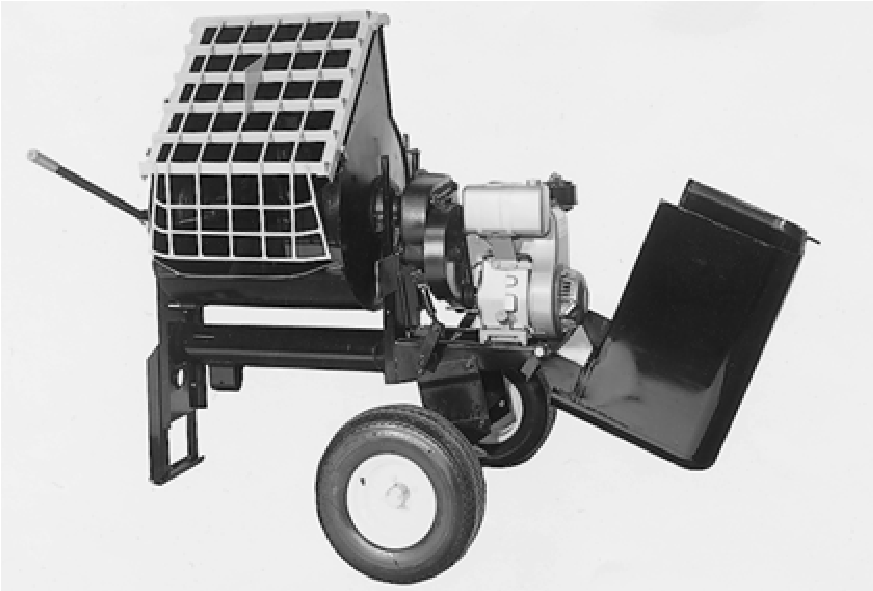

Stone Construction Equipment Champion mixer sports a special cowl design For increased engine airflow, the Stone Champion 1285PM mortar mixer features a cowl that is said to provide five times more ventilation than is typical. With a capacity of 12 cubic feet, the machine is equipped with the manufacturer’s patented “power blend” mixing action—an arrangement of durable rubber and steel blades that rotate in a triple-eight configuration, which constantly divides and recombines the mixture for a fast, smooth, and uniform mix.

No spam, notifications only about products and updates.

Having dealt with MK Diamond Products and the Delahauts since the mid 1990’s it is sad to hear the news that they have closed their

I’ve told my wife and daughter to never follow a mortar mixer down the interstate. For over 30 years we have sold, rented, and repaired

This question is one of the most frequent mixer related questions our rental staff are asked. Our contractor customers know the importance of using the right tools for the job.

Trowel Trades, a company that specializes in equipment rental, tool retail, repair services, scaffolding and mast climber access solutions, enters the Silver Tier of the Masonry Alliance Program.

Your email was submitted successfully.

YOUR 10% OFF COUPON CODE IS WELCOME10.

See category exclusions below.

Category Exclusions:

Arbortech Brick and Mortar Saw, Compaction, Concrete Mixers, Concrete Walk Behind Saws, Drop Hammers, Grout Hogs, iQ Power Tools, Masonry Block Saws, Masonry Brick Saws, Mast Climbers, Mortar Mixers, Mud Buggy, Saws, Scaffold, Self Dumping Hoppers, Shoring, and Stihl