FREE SHIPPING ON

ALL QUALIFYING ORDERS

Enter your email below to join our mailing list:

Read any instruction manual for a fall protection lanyard or SRL, and you’ll no doubt read about fall clearance. That, of course, is the minimum distance required between the worker and next lower level (be it part of the building or the ground) to ensure that, in the event of a fall, there is sufficient room to allow the fall protection gear to do its thing and prevent the worker from impacting something very hard. In tandem with calculating fall clearance is being aware of, and avoiding, swing falls – especially when using an SRL.

First, a definition. According to ANSI, a swing fall is:

A pendulum-like motion that occurs during and/or after a vertical fall. A swing fall results when an authorized person begins a fall from a position that is located horizontally away from a fixed anchorage.

Given the fact that most workers aren’t standing directly under (or over, in the case of foot-level tie off) the anchor point at the onset of a fall, this means that nearly every fall has some swing potential. But, unlike vertical fall clearance, which can be calculated to the foot, a swing fall is a much more variable and complicated thing to consider, and requires some out-of-the box thinking.

Before moving on, I want to clarify that when I engage the concept of a swing fall, the fact is what I’m trying to show is the potential danger not necessarily of swinging, but of swinging into something. The whole point of being aware of how swing falls happen is to ensure proper clearance in a worst-case scenario.

GETTING THE WHOLE PICTURE

First, it’s important to remember that a swing fall is a three-dimensional event. When we look at images on a page that show an example of a fall, it is necessarily in two dimensions, X (left and right) and Y (up and down). The problem with paper (and computer screens), is that they don’t do a great job of showing the third, Z, (close to far) dimension. Second, the dangers of a swing fall are not fixed, meaning that hazards can change (quickly) over time, and it is necessary to adjust your position (or surroundings) to maintain a safe working environment.

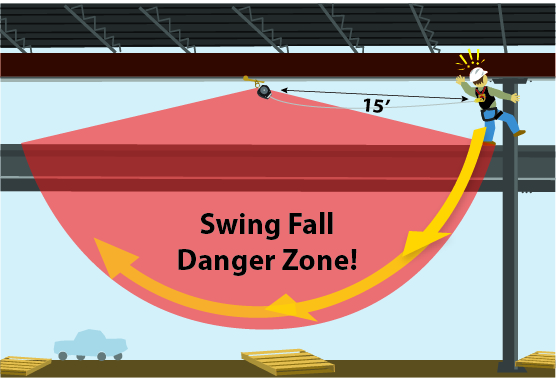

To address the first issue, let’s look at a common view of a swing fall:

SwingFall1

In this example, the worker has walked approximately 15 feet out from his anchor point along the beam. If he were to fall and initiate a swing fall, his general direction of motion would be indicated by the red Swing Fall Danger zone. If there were any obstructions in this zone, our worker would be at risk for an impact, increasing the risk for severe injury or death. But this view only tells half of the story.

A VIEW FROM THE TOP

The next picture is an overhead view of the same job site.

SwingFall2

When looking at the swing fall from above, it becomes quite apparent that what at first looked like a relatively contained danger zone gets much larger – fast. In the first picture, it might seem that the real risk to the worker exists mainly underneath, or alongside the beam in the area indicated. But the reality is that there is a kind of “cone of danger” that exists under the anchor point that extends in all directions, not just along the beam. In this case, the base of that cone is at least twice as long as the lifeline at the onset of the fall.

The reason we need to think in three dimensions when considering a swing fall is that not only can we not predict when a swing fall occurs, we also can’t predict how a fall will occur. It’s one thing to step wrong and merely fall off a (in this case) beam, but it is something entirely different to be knocked off forcibly by a swinging truss, another falling co-worker, or any of a thousand other possibilities. In these extreme cases, the path of the falling worker is completely unpredictable. And remember, once a fall occurs, physics takes over, and there is almost nothing the swinging worker can do to stop or change motion or direction; they will continue to swing until all the energy from the fall has dissipated. It’s this latter point that creates the “cone of danger” I mentioned before. As the worker swings, the ever-changing forces at play will swing him into (somewhat) of a cone shape. To see it (safely) for yourself, hang your car keys from a string or lanyard, raise your keys until the string is taught, let go, and watch what happens. If you pay attention to the motion of the keys until they stop, you will see they do not move in a perfectly straight line, but eventually, some form of cone. This is exactly what happens in the event of a swing fall.

CHANGE IS CONSTANT

An important piece of the “cone of danger” is that the size of the cone is dynamic, and depends (when using an SRL) on how much of the lifeline is extended at the moment of the fall. This is why it is critically important to properly calculate your fall and swing clearance given the worst-case scenario, and use equipment that is compatible with the situation. Unfortunately, there have been instances when a worker used an SRL with a lifeline length that exceeded their fall/swing clearance and they were injured during a fall. Keep this in mind; a full step for an adult is about 3 feet, so every step you take past your initial calculation, you’ll need to add 3 more feet to your swing clearance (cone of danger). As practical as it may sound to use an SRL with a long lifeline and simply “pay attention” to your distance from the anchor so you can cover a wider range of jobsites and situations, this is a potentially deadly mistake when you decide to “reach” for something momentarily and find yourself with no remaining swing clearance. DON’T DO IT!

Another aspect of the swing fall that must be considered is that hazards may enter or exit your cone of danger without you doing a thing. In the above pictures, while the worker is walking the beam paying attention to what is above him, there are likely also workers at ground level doing something completely different and maybe not paying attention to what is above them. If a forklift driver happened to drop off building materials underneath the beam worker, he might very well be endangering the worker by intruding into his cone of danger without even knowing it. Or, say over the course of the day additional beamwork or walls were installed, you had better get with your onsite competent person to ensure that the fall/swing clearance you started with is still valid for your new situation. Workers at height must stay keenly aware of their surroundings, noticing even seemingly common changes in their work environment that may inadvertently create a hazardous situation in the event of a fall.

No spam, notifications only about products and updates.

Having dealt with MK Diamond Products and the Delahauts since the mid 1990’s it is sad to hear the news that they have closed their

I’ve told my wife and daughter to never follow a mortar mixer down the interstate. For over 30 years we have sold, rented, and repaired

This question is one of the most frequent mixer related questions our rental staff are asked. Our contractor customers know the importance of using the right tools for the job.

Trowel Trades, a company that specializes in equipment rental, tool retail, repair services, scaffolding and mast climber access solutions, enters the Silver Tier of the Masonry Alliance Program.

Your email was submitted successfully.

YOUR 10% OFF COUPON CODE IS WELCOME10.

See category exclusions below.

Category Exclusions:

Arbortech Brick and Mortar Saw, Compaction, Concrete Mixers, Concrete Walk Behind Saws, Drop Hammers, Grout Hogs, iQ Power Tools, Masonry Block Saws, Masonry Brick Saws, Mast Climbers, Mortar Mixers, Mud Buggy, Saws, Scaffold, Self Dumping Hoppers, Shoring, and Stihl